As the automotive industry flourishes globally, F6 was already part of in the automotive market with high-performance industrial adhesive tapes. Our adhesive solutions have developed continuously in response to increasing customer demands. Drawing upon years of rich experience serving prominent automotive manufacturers such as BMW, Mercedes-Benz, Volkswagen throughout the supply chain, F6 has developed specialized adhesive systems highly tailored to the automotive industry. Nowadays, our functional double-sided adhesive tapes have emerged as pioneers in the automotive industry adhesive tape.

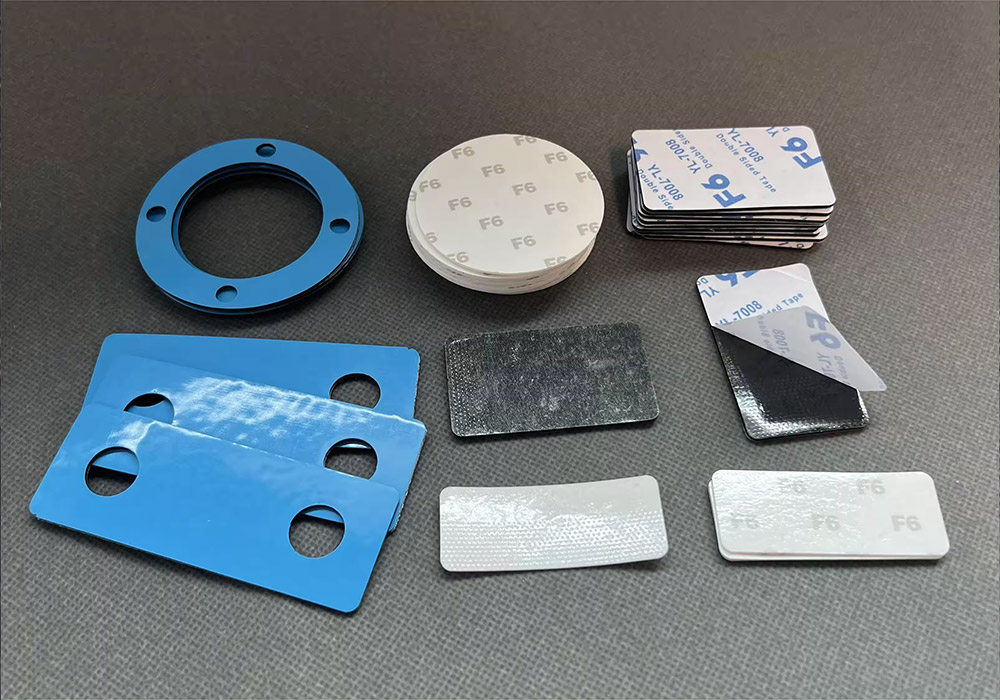

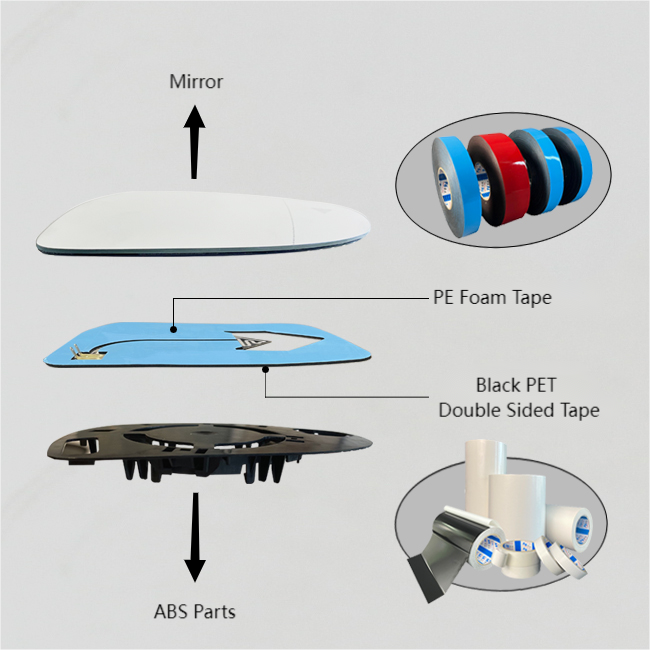

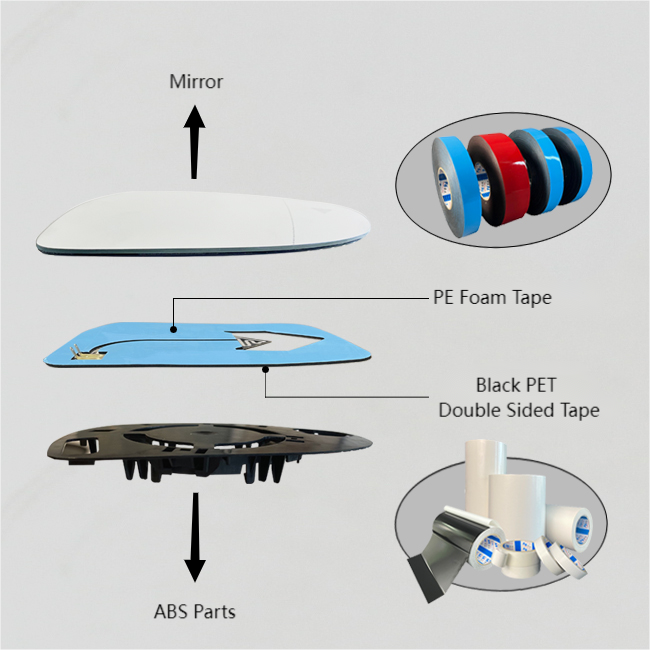

Exterior Rearview Mirror Structure

The exterior rearview mirror is composed of Mirror housing, Electronic components, Base plate, Heating element, and Mirror glass. F6 PET double-sided tape and PE foam tape will help to bond the ABS plastic parts and glass in the structure.

Feature & Application

All double-sided adhesive tape series used in automotive applications exhibit outstanding adhesive performance. PET Double-sided Adhesive Tape (F708) is characterized by excellent peel adhesion, push-out resistance, shear resistance, and high impact resistance. Meanwhile, polyethylene foam tape(F0805K) possesses exceptional adhesion, high temperature resistance, and shock absorption and sealing capabilities.

Therefore, these series are suitable for demanding applications such as automotive interior parts, nameplates, or rear view mirrors, membrane switch. The PET Double-sided Adhesive Tape used in these series exhibits excellent good die-cuttability.

Product Criteria

All F6 products are developed on the basis of scientific research and undergo extensive critical testing. We strive for highest quality in our internal processes, and final products. Under strict adherence to the ISO 9001, all products of F6 have obtained basic compliance with RoHS, REACH, CA 65, as well as the high standards required in the automotive industry, such as Mercedes-Benz V/W205 testing.

ROHS, REACH, CA 65, V/W205 and other required certificates will be promptly updated according to validity period and customer demands.

Partner

▶ Volkswagen

▶ Toyota

▶ Mercedes-Benz

▶ Audi

▶ BMW

▶ Ford

Applicable Products

▶ PET Double Sided Tape —— F708

▶ Polyethylene Foam Tap —— F0805K

Test Items

F6 conducts long-term, large-scale precision testing experiments for exterior rear view mirror solutions with a professional testing team to explore and determine the most suitable and economical adhesive products. Some tests are as follows:

▶ 180°Peeling Strength for Covered/Open Side

▶ 180°Peeling Strength for Each Substrate

▶ Testing Condition of 80℃ Holding Power

▶ Initial Tack /Quick Stick Method

▶ 180°& 90°Peeling Adhesion After Aging

We are confident that with more than ten years of professional R&D and production experience, as well as long-term cooperation and communication with customers, I have very outstanding advantages in the automotive field, especially the pasting and fixing of interior and exterior automotive parts. Look forward to more needs and challenges from you and continue to promote the development of the industry.

For more specific solutions regarding rear view mirror heaters, please discuss further with our technical engineers!

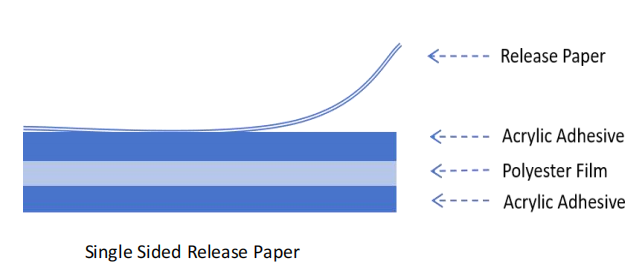

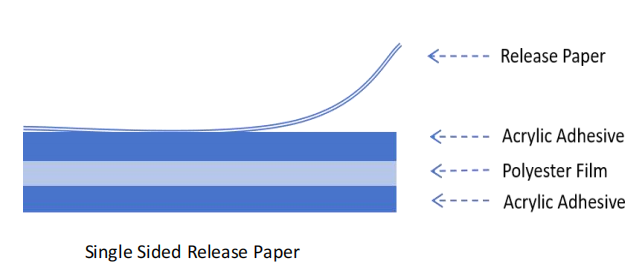

Construction-F708 PET Double Sided Tape

|

|

|

・110 µm white PCK liner With Blue F6® Classic Double Sided Tape Logo

|

・110 µm white PCK liner With Blue F6® Classic Double Sided Tape Logo

|

|

・50 µm Premium Acrylic Adhesive

|

・50 µm Premium Acrylic Adhesive

|

|

・25 µm Flexible Polyester Film

|

・25 µm Flexible Polyester Film

|

|

・50 µm Premium Acrylic Adhesive

|

・50 µm Premium Acrylic Adhesive

|

| |

・110 µm white PCK line

|

Performance Testing

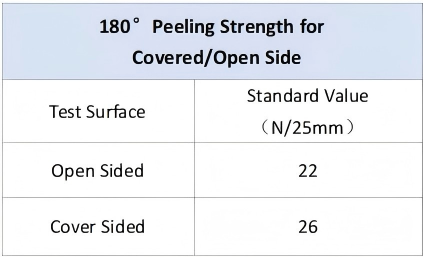

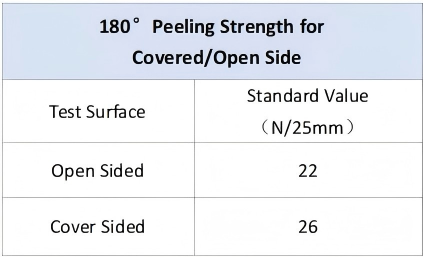

1.180°Peeling Strength for Covered/Open Side

— Unit: N/25mm

— Substrate: 50mm*145mm 304 SUS plate

— Sample Width: 25mm

— Backing Material: PET film

— Application Condition:

3 pass back and forth with a 2.5kg roller

— Peeling Speed: 300mm/min — Peeling Angle: 180°

— Measurement Condition: 23℃/65%RH×30min

— Measurement Temperature: Normal Temperature

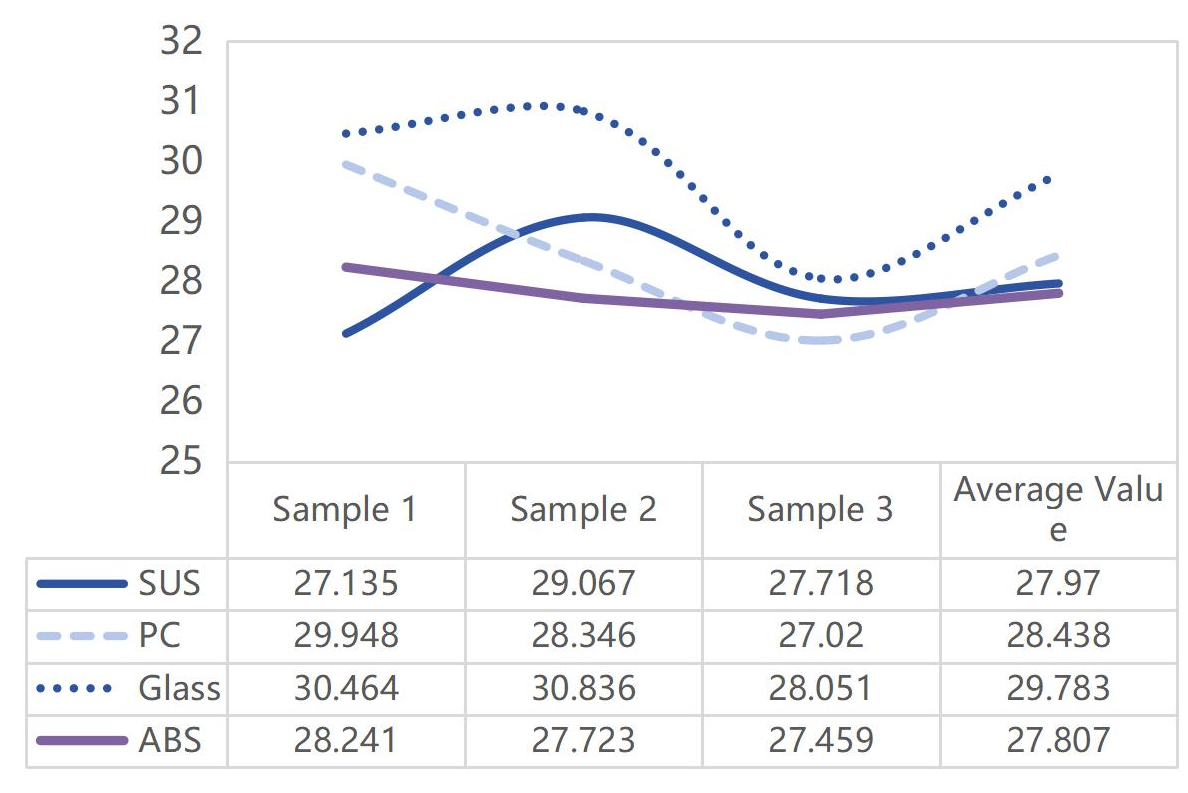

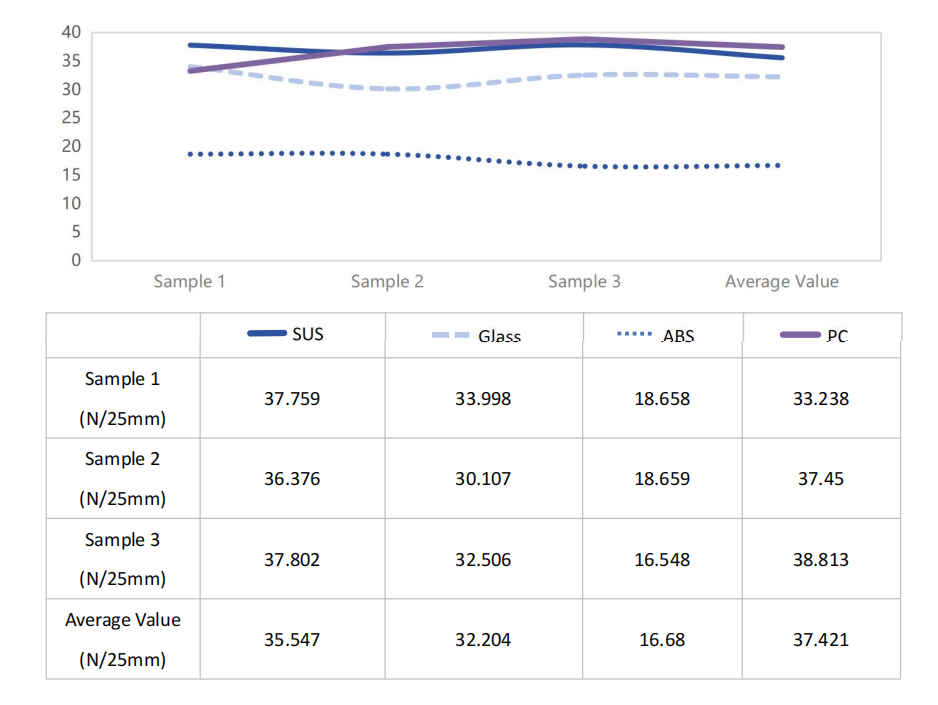

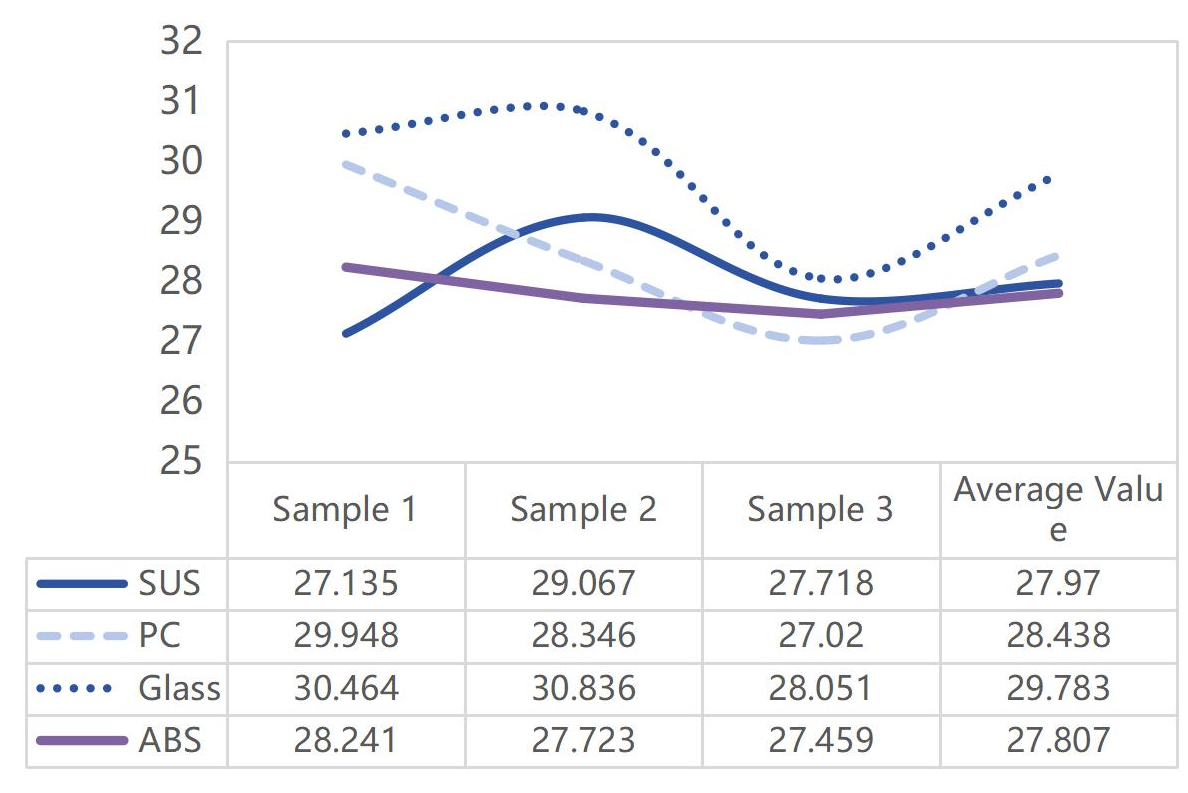

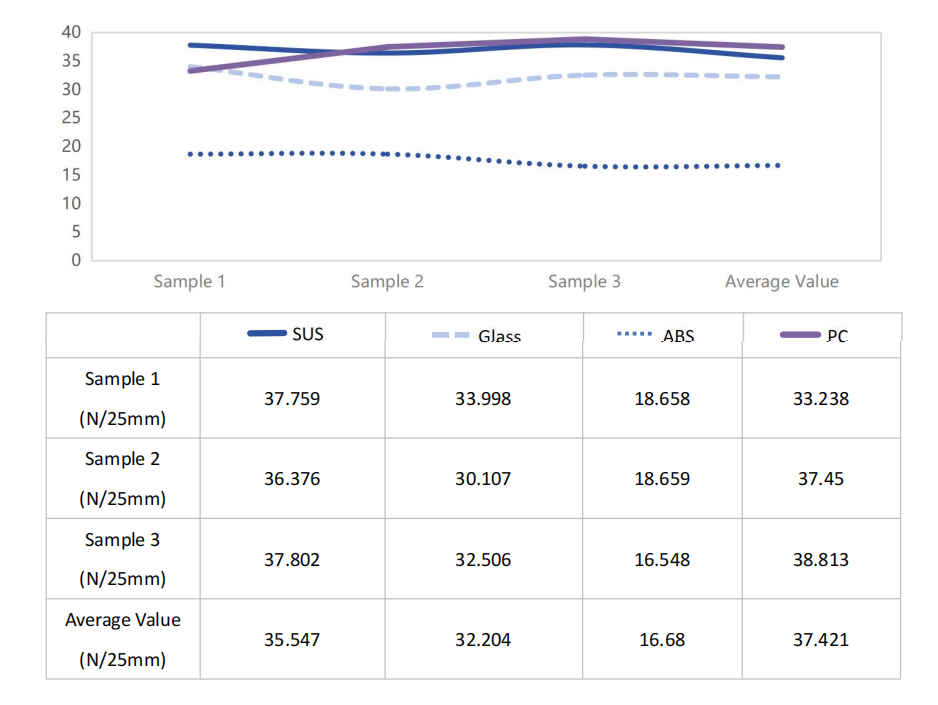

2.180°Peeling Strength for Each Substrate

— Unit: ℃/1h

— Substrate: SUS/PC/Glass/ABS

*Conventional Lamination Materials for Reflective Mirror

— Sample Width: 25mm

— Backing Material: PET film

— Application Condition:

3 pass back and forth with a 2.5kg roller

— Peeling Speed: 300mm/min

— Peeling Angle: 180°

— Measurement Condition: 23℃/65%RH×30min

Note: The special double sided blue glass rear view mirror typically features a surface coating containing specific ingredients, which may affect the adhesive properties of tape. It requires the use of adhesionpromoters for optimal adhesion.

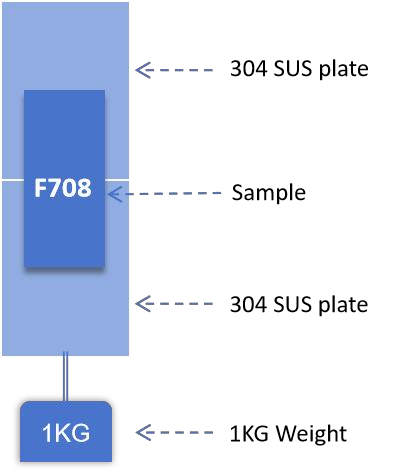

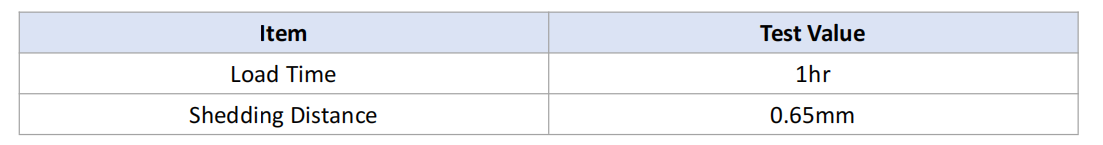

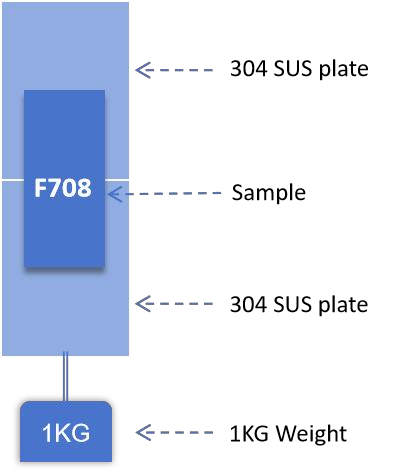

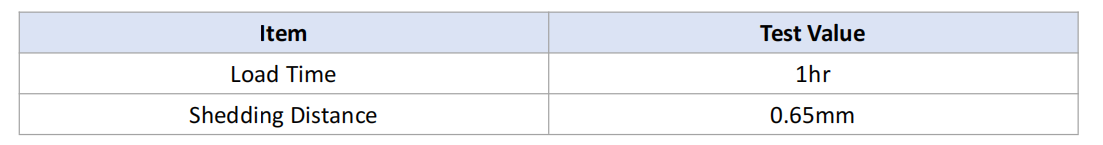

3. Testing Condition of 80℃ Holding Power

— Unit: mm/hr

— Substrate: 50mm*145mm 304 Stainless Steel

—Pressing condition:

3 pass back and forth with 2.5kg at 23℃/65%RH

— Applying condition :80℃/65%RH×30min

— Tape area :50mm*50mm

— Load : 10N(1kg)

— Load time : 1hr

Test result:

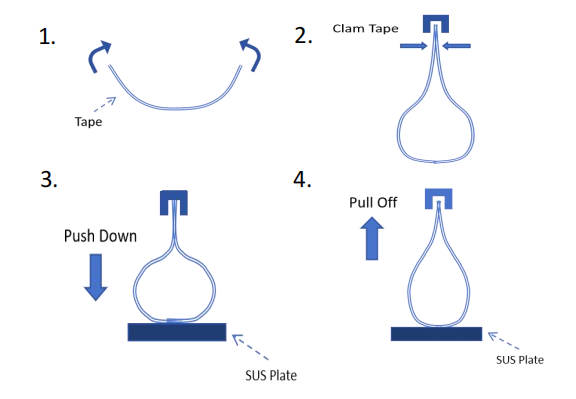

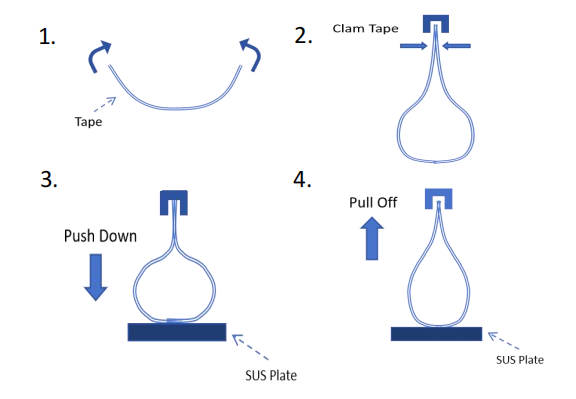

4.Loop Tack /Quick Stick Method

— Unit:N/25mm

— Substrate: Glass/PC/ABS/Plate

— Sample Width:22mm*175mm

— Peeling Speed: 300mm/min

— Contact Area:25mm*25mm

— Measurement Temperature: 23℃/50%RH

Test result:

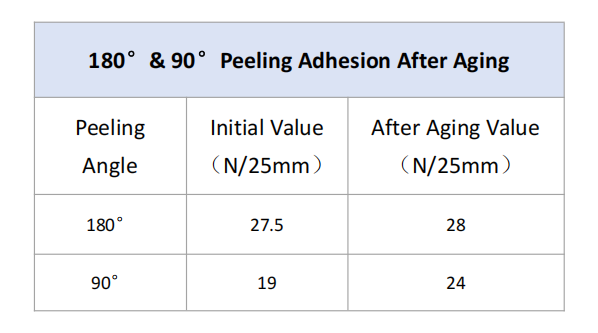

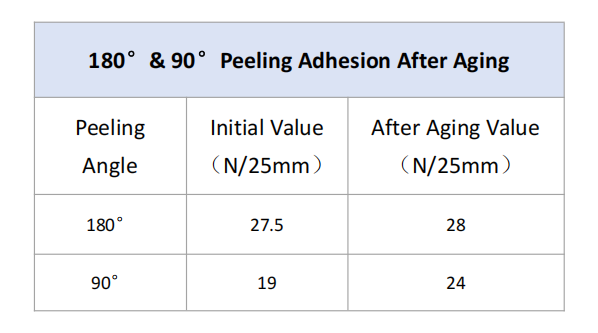

5.180°& 90°Peeling Adhesion After Aging

— Unit:N/25mm

— Sample Width:25mm

— Backing Material: PET film

— Application Condition:

3 pass back and forth with a 2.5kg roller

— Peeling Speed: 300mm/min, 100mm/min

— Peeling Angle: 180 °, 90°

— Measurement Temperature: 23℃/65%RH

— Anti-aging conditions:

*[80°C/60%RH×4hrs ⇒ -30°C/60%RH×4hrs⇒23°C/60%RH×4hrs] ×4 cycles

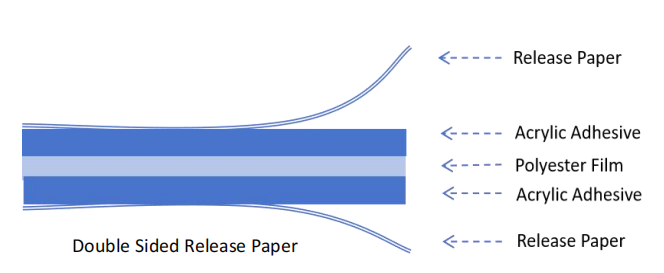

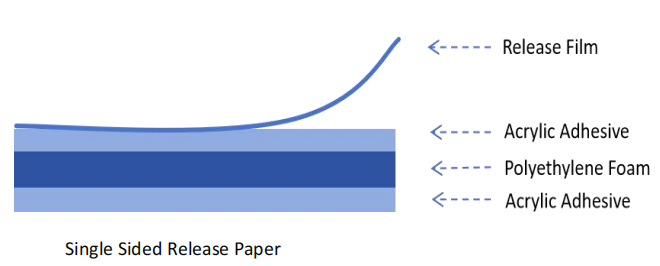

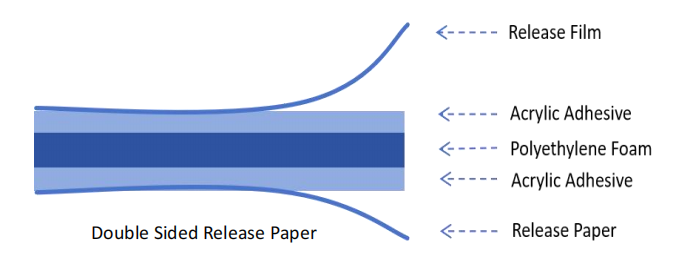

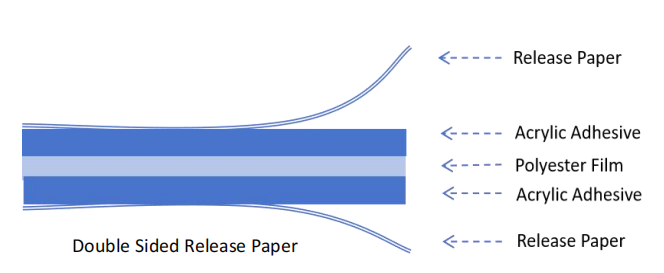

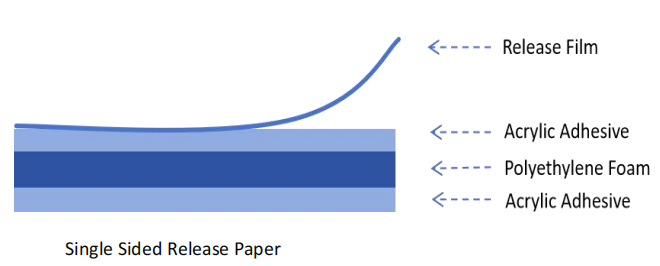

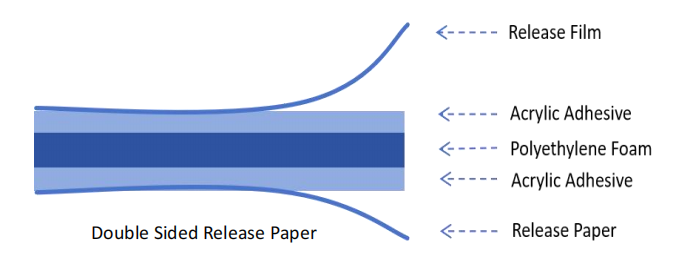

Construction – F0805K PE Foam Double Sided Tape

|

|

| ・110 µm Release liner |

・110 µm Release liner |

| ・50 µm Premium Acrylic Adhesive |

・50 µm Premium Acrylic Adhesive |

| ・500 µm Polyethylene Foam |

・500 µm Polyethylene Foam |

| ・50 µm Premium Acrylic Adhesive |

・50 µm Premium Acrylic Adhesive |

| |

・100µm White Release Paper |

Performance Testing

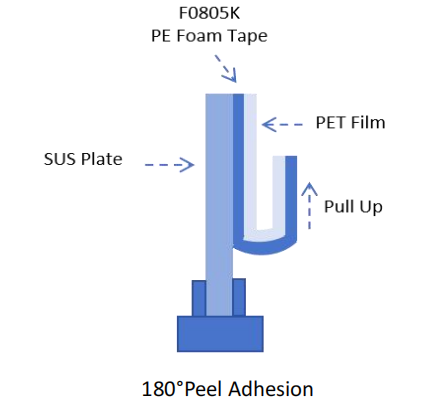

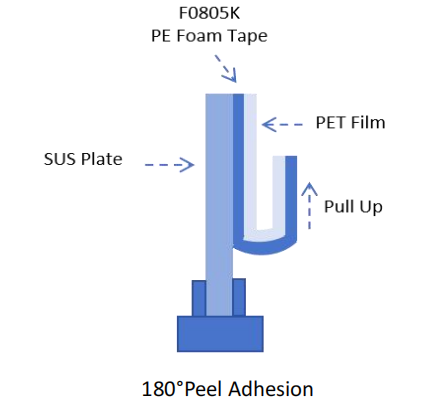

1.180°Peeling Adhesion by Substrates

— Unit:N/25mm

— Sample Width:25mm

— Backing Material: PET film

— Application Condition:

3 pass back and forth with a 2.5kg roller

— Peeling Speed: 300mm/min

— Peeling Angle: 180 degree

— Measurement Temperature: 23℃/65%RH

Test result:

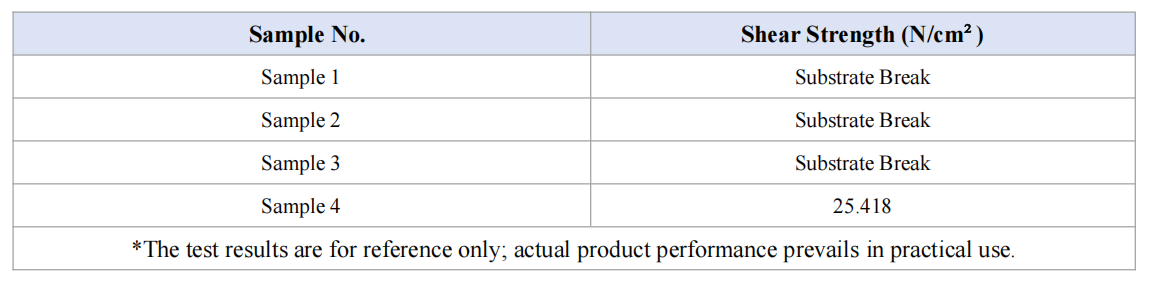

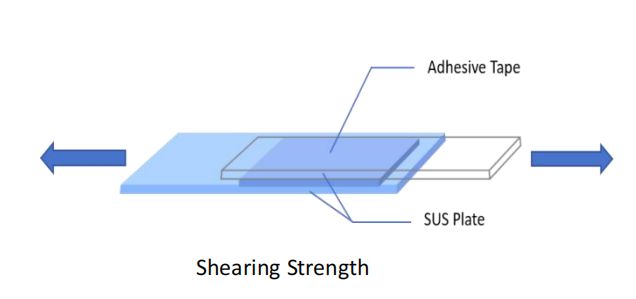

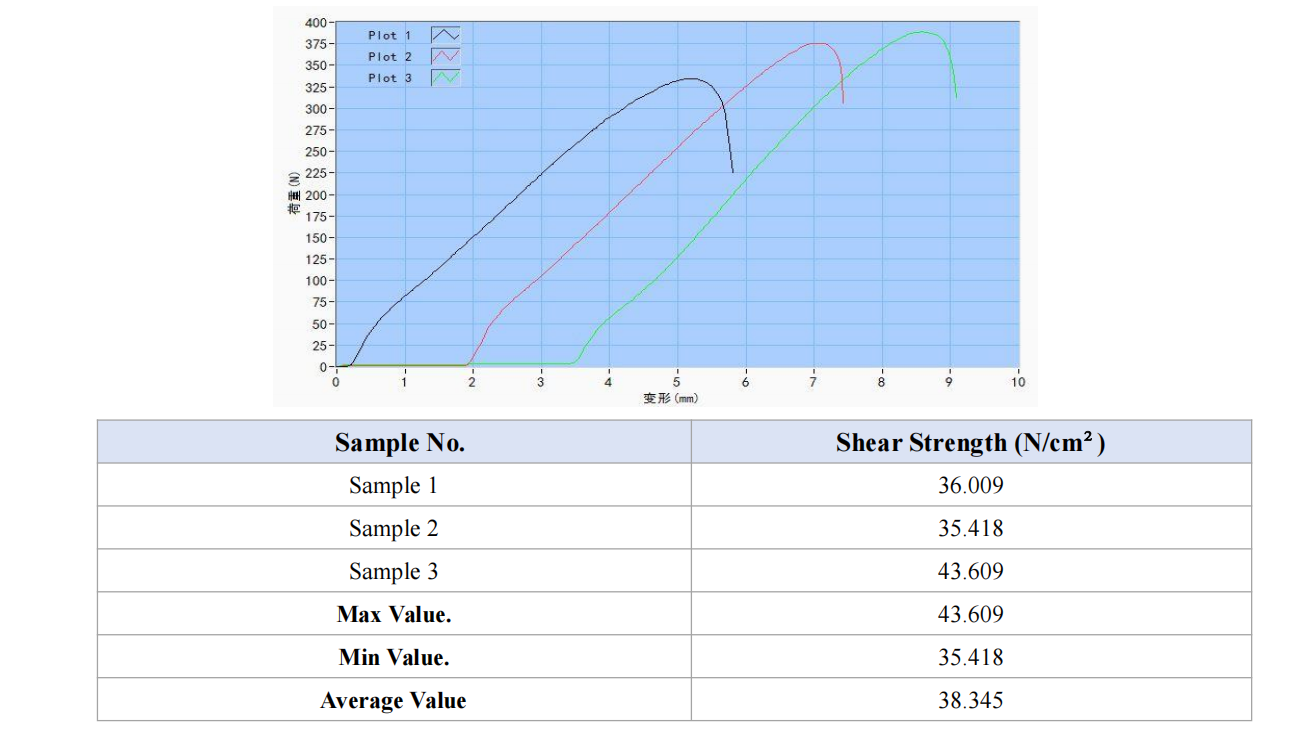

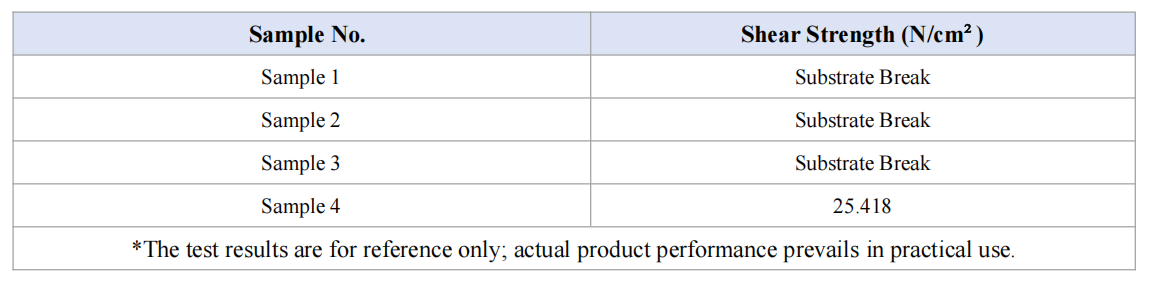

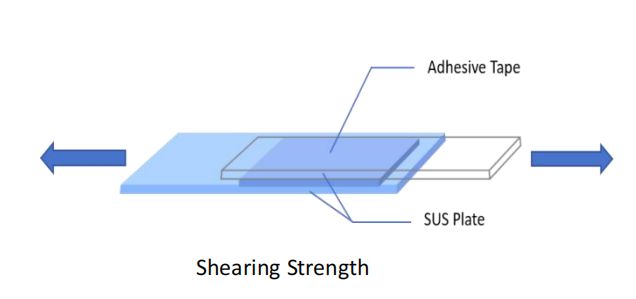

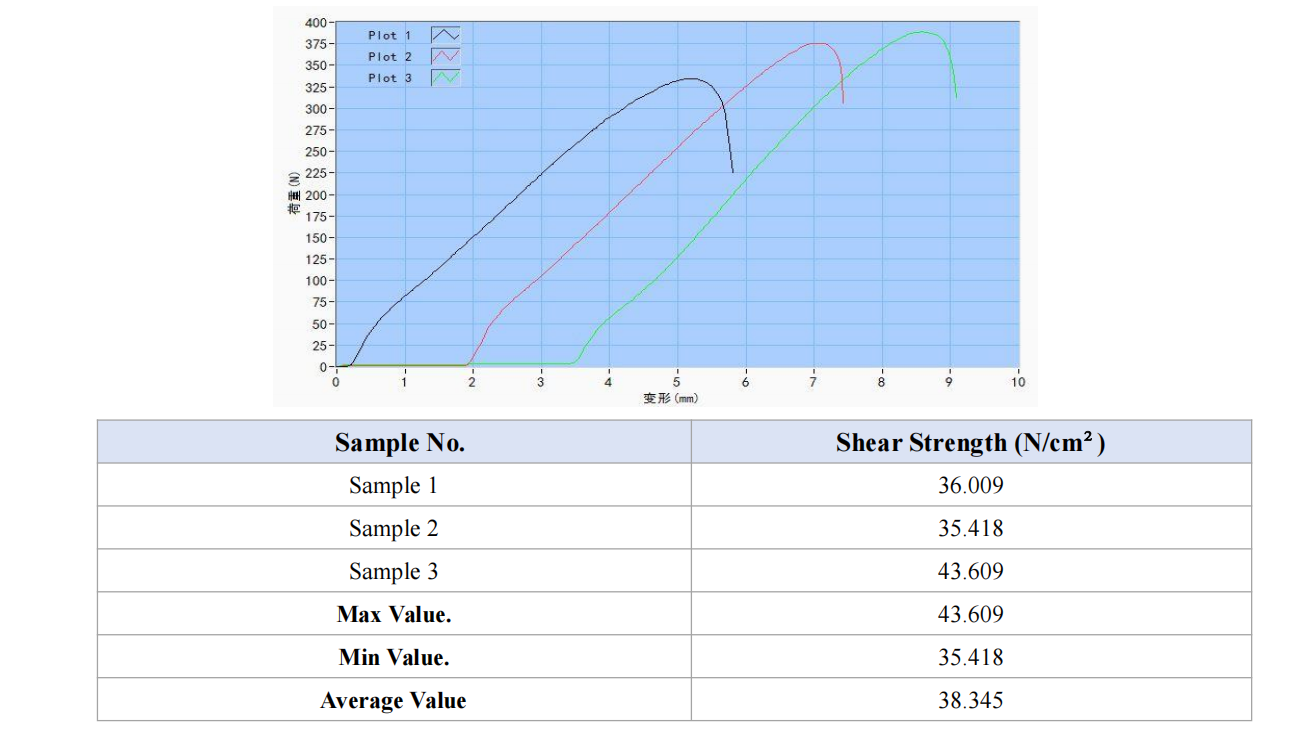

2.Shearing Strength

— Unit:N/25mm

— Sample Width: 20mm x 20mm

— Backing Material: PET film

— Application Condition:

3 pass back and forth with a 2.5kg roller

— Peeling Speed: 50mm/min

— Measurement Temperature: 23℃/65%RH

Test result:

Responsibility of supplying

We will strictly control the quality of each batch of products and processes.

The following terms are for reference only.

— Inspection reports for each batch of shipped products will be provided post-production.

— When significant changes that may affect product quality, such as process modifications or substrate changes, occur, we will provide

relevant reports to the first party for their assessment of potential adverse impacts on subsequent product quality.

— Under normal conditions, there’s a six-month quality guarantee from the production date. If any quality issues arise within one month

of receipt, and the product remains unused with intact packaging and no visible damage, exchanges or refunds can be arranged.

— All notifications and approvals related to the placement of orders shall be in written form, and any changes to the information shall be

notified to the other party with a 15-day advance notice.

— If either party is unable to fulfill its obligations due to force majeure events such as fire, flood, hurricane, earthquake, other natural

disasters, war, terrorism, riot, rebellion, revolution, or internal unrest, the affected party shall be exempt from performance during the

duration of the event.