In our traditional concept, we always think “Thicker tape means stronger adhesion?” Is this really the truth? NO.

Actually, adhesion mainly depends on the adhesive’s formulation(adhesive type, adhesive solids content), the compatibility of the substrate and the adhered object, and coating uniformity. Tape thickness is determined by cushioning or gap-filling needs.Thick tapes aren’t necessarily stronger, and thin tapes can still provide reliable bonding with high-quality adhesives.

Thickness has no direct relationship with Adhesion:

Thickness mainly depends on the carrier and adhesive layer.

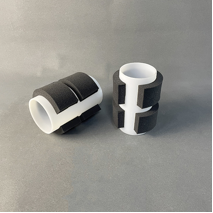

Thick double-sided tapes (e.g., foam tapes) generally offer strong gap-filling properties, compensating for uneven surfaces.

Thin double-sided tapes (e.g., PET, nonwoven carriers) are better suited for flat, smooth surfaces, ensuring better aesthetics and fit.

Adhesion mainly determined by adhesive formulation.

Regardless of thickness, the true bonding performance is decided by the pressure-sensitive adhesive itself, such as acrylic, rubber, or silicone systems.

Tapes of the same thickness but different adhesives may vary significantly in initial tack, holding power, temperature resistance, and aging resistance.

Summary:

1.Thickness ≠ Adhesion.

2.Thick tapes are generally more suitable for rough and irregular surfaces.

3.Thin tapes are more suitable for smooth and precision bonding.

4.Adhesion strength should be judged by the adhesive system and performance parameters.

Application Comparison by Tape Thickness:

| Thickness Range | Typical Carrier | Characteristics | Typical Applications |

|---|---|---|---|

| Ultra-thin (≤0.1mm) | PET, carrier-free | Excellent appearance, high transparency, minimal space, ideal for precision bonding | Smartphones, tablets, display lamination, membrane switches, nameplate attachment |

| Medium (0.1–0.3mm) | Nonwoven, tissue | Good flexibility, strong initial tack, easy handling, suitable for flat surfaces | Home appliances, labels, decorative trims, paper converting |

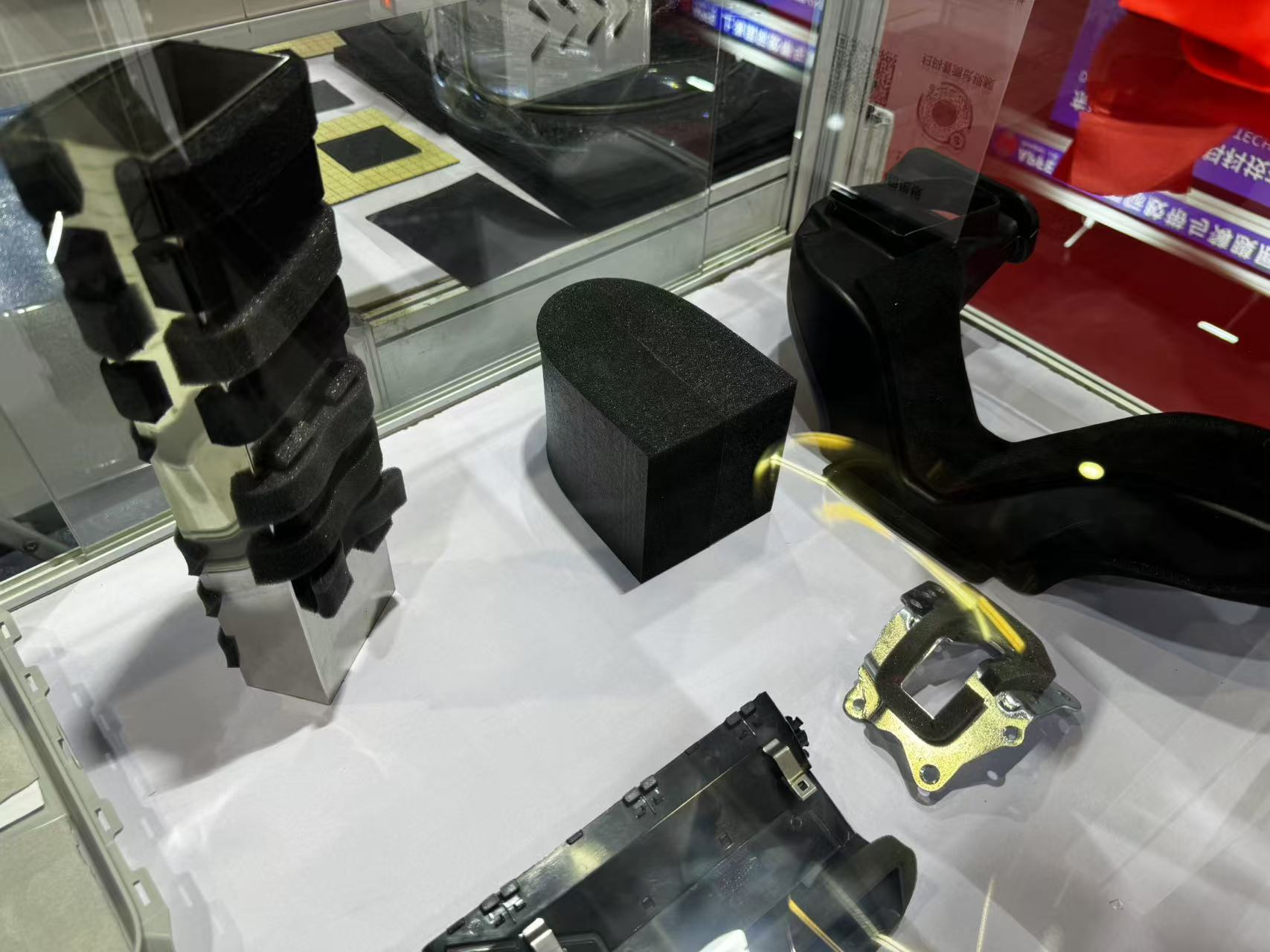

| Thick (0.3–1.0mm) | Foam, cloth | Excellent gap filling, cushioning, shock absorption, reliable on rough surfaces | Automotive interiors, construction materials, metal-to-plastic bonding |

| Extra-thick (>1.0mm) | High-density foam | High load-bearing, impact resistance, vibration damping, long-term holding power | Glass curtain walls, automotive components, structural bonding (can partially replace screws/rivets) |

Key Takeaways:

Thin ≠ Weak Adhesion → Thin tapes can achieve strong bonding but require smooth surfaces.

Thick ≠ Stronger Adhesion → The key advantage of thick tapes lies in gap filling and impact resistance, not simply stronger adhesive force.

Final bonding performance depends on:Adhesive System + Thickness + Substrate Characteristics.

Characteristics of Foam Materials:

Surface roughness and porosity;

Relatively low surface energy (e.g., PE/EVA foams are difficult to bond with general adhesives);

Softness and elasticity, prone to shifting during lamination and service.

Advantages of F6 Double-Sided Tape:

Acrylic PSA:excellent aging resistance, temperature resistance, and holding power.

High initial tack + long-term adhesion, maintaining reliable bonding even on rough or low surface energy materials.

Multiple thickness options (commonly tissue, PET, or nonwoven carriers) to balance fit and cushioning.

F6 double-sided tapes use Acrylic Pressure-Sensitive Adhesive, offering excellent aging, temperature, and weather resistance, making them suitable for long-term applications in automotive, electronics, and outdoor use. While their cost and quality may be less obvious in general bonding, their advantages shine in specialized foam bonding (PU, PE, EPDM, etc.), providing precise substrate compatibility, strong stability, weather resistance, conformability, and superior cost-effectiveness.”

Typical Applications:

Automotive: bonding of foams (PU, PE, EVA) with plastics/metal parts.

Appliances::attachment of cushioning strips and sealing foams.

Electronics:foam pads, shock-absorbing foams combined with housings.

Construction:sealing foams, sound insulation materials.

Conclusion:

In summary, we must clearly know that “Thickness ≠ Adhesion” and learn to judge bonding performance based on the characteristics of the surface being bonded and the adhesive system (such as Acrylic PSA). F6 Double-Sided Tape delivers strong weather and temperature resistance, excels in bonding rough or low-energy surfaces, and offers high tack with customizable thickness. Its balance of performance and cost makes it ideal for automotive, appliance, electronics, and construction applications.