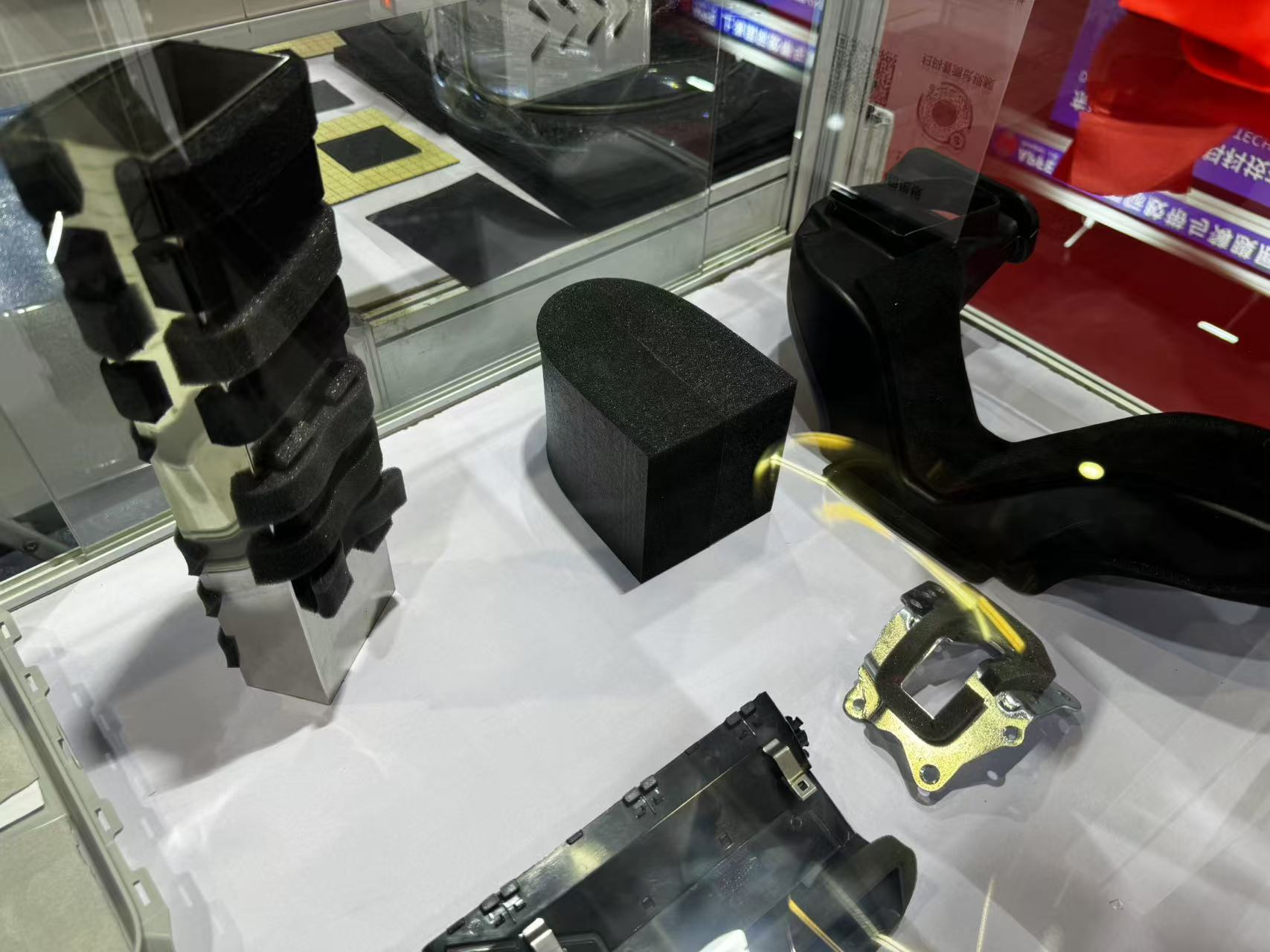

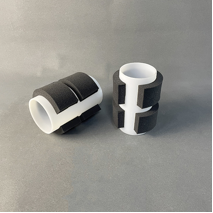

In automotive air conditioning systems, PU foam in the air ducts may seem inconspicuous,

but it plays a crucial role:

Outstanding Noise Reduction – As an acoustic barrier in the airflow passage, PU foam absorbs and blocks broadband noise (especially mid-to-high frequency wind noise) generated by airflow, significantly improving the NVH (Noise, Vibration, and Harshness) performance of the cabin and enhancing driving comfort and perceived quality.

Efficient Thermal Insulation, Energy Savings, and Protection – Its combined closed-cell/open-cell pore structure forms an effective thermal barrier, reducing heat loss along the duct walls, lowering A/C energy consumption, and maintaining air delivery temperature. This also prevents condensation on the outer wall of the duct caused by temperature differences, eliminating dripping water that could potentially corrode the vehicle chassis sheet metal, wiring connectors, or critical electronic components, thereby improving the system’s long-term reliability.

|

1223123123 |

123123123123 |

To achieve efficient, reliable, and environmentally friendly bonding of PU foam to the complex three-dimensional surfaces of air ducts, our newly developed F5001A Water-Based Acrylic Pressure Sensitive Adhesive F0965 stands out for its unique integrated performance, becoming the most promising bonding solution available today.

1. Core Application Advantages of F5001A- F0965

1. Environmentally Friendly and Healthy Choice

Significant low-odor, low-VOC characteristics vs. solvent-based PSA:

The water-based system uses water as the dispersion medium, containing little to no organic solvent. During production, coating, assembly, and in-vehicle use, its VOC (volatile organic compounds) and odor emissions are far lower than those of solvent-based adhesives. It complies with increasingly stringent environmental regulations (GB/T 27630, VDA 270, ISO 12219) and OEM standards, ensuring worker health and improving in-cabin air quality.

Practical Value: Eliminates the need for costly exhaust gas incineration systems (RTO) and their operating costs.

2. Excellent Environmental Durability

Superior heat and humidity resistance vs. hot melt PSA:

F0960 is made of acrylate polymers with outstanding aging resistance and molecular stability. In long-term high-temperature (>80°C), high-humidity (85°C/85% RH) conditions inside the engine bay or dashboard, its adhesion strength degrades far less than hot melt adhesives. It has anti-yellowing properties and avoids adhesive layer chalking, creep, or delamination after prolonged service, ensuring long-term bonding effectiveness.

Practical Value: Guarantees that PU foam remains securely bonded under harsh climates and aging conditions, preventing NVH deterioration or condensation risks caused by detachment.

3. Clear Cost Advantages

More competitive total cost vs. solvent-based PSA:

While unit prices may vary, water-based adhesives significantly reduce overall costs:

-

No hazardous chemicals: Not classified as hazardous materials, greatly reducing storage (no special warehouse needed), logistics, and safety compliance costs.

-

Lower compliance costs: No need for expensive exhaust treatment equipment (RTO).

-

Reduced energy consumption: Some processes do not require high-temperature drying tunnels (unlike hot melts that need immediate heating).

Practical Value: From a total cost of ownership (TCO) perspective, F0965 offers manufacturers a more advantageous economic outcome.

4. Improved Manufacturing Efficiency

Efficient assembly and high-reliability design:

-

Fast pre-fixation: The pressure-sensitive nature allows PU foam to be temporarily fixed immediately after application, with no “cooling period” needed, simplifying processes and increasing assembly speed.

-

Full coverage without gaps: The adhesive conforms tightly to all duct corners, bends, and uneven areas, ensuring complete sealing.

Compared with ultrasonic welding:

-

No perforation risk: Avoids localized perforation caused by energy concentration during welding.

-

Excellent conformability: Eliminates small cavities caused by poor fit, which are key spots where moist air condenses. By eliminating cavities, condensation risks are minimized at the source.

Practical Value: Enhances production takt time, eliminates sealing defects (perforations, gaps), and ensures 100% sealing reliability at delivery.

5. Lower Equipment Investment Requirements

Coating only requires water-based adhesive coating equipment (gravure, roller, knife coating) and standard hot-air drying tunnels (lower temperature and shorter time compared to solvent-based adhesives).

Compared with solvent adhesives: No multi-million-RMB RTO investment needed, nor complex high-temperature fast-drying processes.

Compared with hot melt adhesives: No high-temperature melting tanks, precision temperature controls, or anti-stringing devices required.

Compared with UV hot melts: No UV equipment needed, no concerns about irradiation intensity affecting tack or holding power, and better dispersibility for adding pigments or flame retardants.

Practical Value: Lower initial equipment investment and greater flexibility for production lines—especially suitable for small/medium-scale production or rapid product line switching.

2. Key Considerations for Successful Application

Despite the significant advantages of F0965 achieving optimal performance requires attention to:

-

Substrate Compatibility – The surface properties of PU foam (density, open-cell ratio, surface tension) are critical to adhesive wetting and bond strength. Ensure the adhesive is well matched with both PU foam and duct materials (often PP, ABS, or modified plastics). Surface pretreatment (e.g., corona, plasma) may be required.

-

Precision Coating Control – Adjust solid content, coating weight, uniformity, and drying parameters (temperature, airflow, time) according to PU foam characteristics and bonding needs, ensuring the adhesive is fully dried and activated for ideal tack/holding balance.

-

Quality Control System – Implement strict incoming adhesive inspections (viscosity, solids content, pH) and bonded component testing (peel strength at room temperature, strength after high-temp/high-humidity aging, thermal cycling resistance, VOC/SVOC tests) to ensure consistent batch quality.

Conclusion

Water-based acrylic pressure sensitive adhesives provide an optimal solution to the challenges of bonding PU foam in automotive air ducts, meeting environmental regulations, ensuring long-term durability, reducing production costs, improving assembly efficiency, and ensuring structural reliability.

Its low-VOC characteristics meet health and environmental standards, while its excellent aging resistance ensures bonding reliability over the product’s full life cycle. Cost advantages enhance manufacturing competitiveness, and its ability to achieve seamless full-coverage bonding eliminates perforation risks and condensation issues seen in traditional methods such as ultrasonic welding.

As the automotive industry moves toward environmentally friendly, lightweight, high-performance, and cost-effective manufacturing, WB-APSA will become the mainstream bonding choice for PU foam in air ducts. Materials R&D teams and process engineers should work together to continuously optimize adhesive formulations and coating processes, fully unleashing its potential to build the next generation of eco-friendly, quiet, efficient, and reliable automotive air conditioning systems.